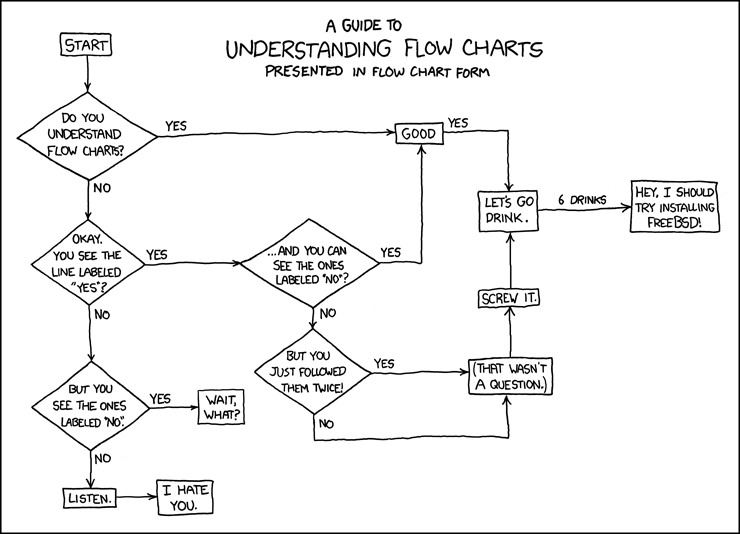

If you have not visited xkcd it's the geek's cartoon of choice, and as a self admitted operations geek I enjoy the humour. Process and values steam mapping and flow charts are a big part of Lean, so thought this would be suitable

An early Merry Christmas

This blog is designed to give you some pragmatic advice and ideas on how on implementing Lean. I'll use ideas from companies using Lean and others to demonstrate changes to make and how to go about change.

Tuesday, December 21, 2010

Tuesday, December 14, 2010

The Globe and 'Dismal' productivity

The Globe and Mail has another article on Canadian productivity. There have been a series of these over the last year and it is good to see productivity being discussed as an important business issue.

The article contained one wonderful nugget "The pressure is building for companies to do more with less by investing in new processes to boost productivity". I absolutely love the fact that they talk about processes instead of new the normal new equipment or automation.

I'm hoping that this maybe part of the start of business realizing that processes improvement is a key factor in improving business.

The bad bit and sorry there was one was from David Yager, chief executive officer of HSE Integrated Ltd., a Calgary health and safety services company. First he says its tough to boost productivity. Yes it is tough, business is tough we get on with it. Next he says "there’s not much we can do on productivity,” Lean in the service industry is well established maybe not in Calgary but the ideas are all out there. David when was the last time a business process was mapped at HSE? The tough part I suspect is learning to see the waste in HSE Integrated's business processes, accepting they exist and deciding to do something about them. The big issue is not Government regulation as he claims, Canada is relatively free from regulation, Alberta especially, I'm going say the issue is not wanting to see the waste and do something about it.

End of rant.

Post: http://www.theglobeandmail.com/report-on-business/economy/growth/dismal-productivity-growth-bodes-poorly-for-recovery/article1836771/

The article contained one wonderful nugget "The pressure is building for companies to do more with less by investing in new processes to boost productivity". I absolutely love the fact that they talk about processes instead of new the normal new equipment or automation.

I'm hoping that this maybe part of the start of business realizing that processes improvement is a key factor in improving business.

The bad bit and sorry there was one was from David Yager, chief executive officer of HSE Integrated Ltd., a Calgary health and safety services company. First he says its tough to boost productivity. Yes it is tough, business is tough we get on with it. Next he says "there’s not much we can do on productivity,” Lean in the service industry is well established maybe not in Calgary but the ideas are all out there. David when was the last time a business process was mapped at HSE? The tough part I suspect is learning to see the waste in HSE Integrated's business processes, accepting they exist and deciding to do something about them. The big issue is not Government regulation as he claims, Canada is relatively free from regulation, Alberta especially, I'm going say the issue is not wanting to see the waste and do something about it.

End of rant.

Post: http://www.theglobeandmail.com/report-on-business/economy/growth/dismal-productivity-growth-bodes-poorly-for-recovery/article1836771/

Sunday, December 12, 2010

Calgary's Bow Tower reaches the half-way construction mark

Did a little Googling and found this from the Herald. Interesting fact, no material is on site for more than 24 hours. I can understand that, there is not a lot of spare room available at the site. And it also sounds like they have really thought about how to control the flow of labor on and off site, this is an important issue. I was recently doing some work with a company that does wood finishing for building like the Bow. Getting on site and up to the 25th floor was easy. Getting out was not so, I waited 25 minutes. The company had 8 staff on site and were effectively loosing at least 1 man-day every day waiting for the lift. Everything for the building had to go up or down one service lift, all the trades people, inspectors and material.

From the outsider it was obvious this was a system constraint and needed to be managed, which of course it was not. All the trades were expected to start the same time, times were not put aside for delivery. The lead company did not care what pain the sub contractors were under, they did care they were running late. So hours were extended but the wastes in the system, the free hours that could be solved were not looked at.

From the outsider it was obvious this was a system constraint and needed to be managed, which of course it was not. All the trades were expected to start the same time, times were not put aside for delivery. The lead company did not care what pain the sub contractors were under, they did care they were running late. So hours were extended but the wastes in the system, the free hours that could be solved were not looked at.

Ark Hotel Construction time lapse building 15 storeys in 2 days

This is not a blog on lean construction but this is very impressive. Constructing a 15 story building in just 6 days. I suspect an awful lot of pre-construction had happened and there was a lot of inventory sat around waiting for construction to start, so not just in time. The co-ordination of material to site however is just awesome.

Closer to home the Bow is starting to dominate the skyline of downtown Calgary. And props to the guys running the construction they are doing a good job of not causing gridlock down town.

Source: http://www.archdaily.com/88245/video-ark-hotel/

Closer to home the Bow is starting to dominate the skyline of downtown Calgary. And props to the guys running the construction they are doing a good job of not causing gridlock down town.

Source: http://www.archdaily.com/88245/video-ark-hotel/

Saturday, December 11, 2010

Lean in the Bathroom

Now that I've got your attention it is nothing that your were thinking about. The truth is I was grouting the downstairs bathroom and the sin of big batches caught me out. There I am gung-ho to get things done and underestimating how much work is involved. Does that sound familiar? So I get started right in the middle of the tiling. A few minutes later and I'm feeling the pressure I have just put myself under.

By starting slap right in the middle I am now committed to having to complete the biggest surface all in one go. And I'm hurting, I'm learning as I'm going on. I don't know if the grout is mixed right, is it too thick, too thin or have I got it right. Am I pushing it into the space between the tiles nicely. When do I stop applying grout and wipe down the tiles, I know I am behind schedule. Having bitten off the biggest batch I could, I'm taking longer than I want to apply the grout and the grout is drying out more than I want. The low humidity here in Calgary is not helping. By the time I get to wipe down the grout it is not an easy job, I really have to work at it. I'm getting tired, concentration is going, quality is struggling.

Eventually I get the wall done, I take a break, refresh myself and start on the smallest wall. I've learnt the applying process, I can control the rate I cover the wall. I'm in control. The quality of work is good, I'm happy with the work and not stressed. Funny that.

Many lessons we have to learn many times. The problem of big batches is one of the more counter intuitive ideas in Lean thinking and probably one that I will continue to come up against a few more times.

By starting slap right in the middle I am now committed to having to complete the biggest surface all in one go. And I'm hurting, I'm learning as I'm going on. I don't know if the grout is mixed right, is it too thick, too thin or have I got it right. Am I pushing it into the space between the tiles nicely. When do I stop applying grout and wipe down the tiles, I know I am behind schedule. Having bitten off the biggest batch I could, I'm taking longer than I want to apply the grout and the grout is drying out more than I want. The low humidity here in Calgary is not helping. By the time I get to wipe down the grout it is not an easy job, I really have to work at it. I'm getting tired, concentration is going, quality is struggling.

Eventually I get the wall done, I take a break, refresh myself and start on the smallest wall. I've learnt the applying process, I can control the rate I cover the wall. I'm in control. The quality of work is good, I'm happy with the work and not stressed. Funny that.

Many lessons we have to learn many times. The problem of big batches is one of the more counter intuitive ideas in Lean thinking and probably one that I will continue to come up against a few more times.

Wednesday, December 1, 2010

GM Volt Wow and Ouch

The Chevy Volt I think is a great car and was probably one of the good reasons that GM were bailed out. So I was watching this Youtube video of the Chevy Volt being made. You get to see the whole thing in 2 minute a pretty good wow.

That was until 1:17 into the video when I had to say a little ouch to myself. Seeing the operator having to reach up above her head to complete her operation, I started thinking. Mostly I thought OWWW I'm grateful that's not me having to do that, my shoulders would be hurting me. Then I started thinking is that Lean to make someone do an operation like that. Obviously not, there is lots of Motion in reaching up that high. More importantly how does this respect the operator. Not a great deal I suspect as it repeatedly puts them in an uncomfortable working position. Lets hope that Chevy get to Kaizen this issue out.

Friday, November 26, 2010

From Plant magazine - Alberta tackles its productivity gap

Good for Alberta Productivity getting their message out their.

From Plant magazine http://www.canadianmanufacturing.com/fabrication/production/alberta-tackles-its-productivity-gap-9925 .

More good stuff at Productivity Alberta including the Productivity Assessment Tool that I worked on with Productivity Alberta and the Winslow Group who are Edmonton's leading Lean consultants.

Those links

SMED can be as simple as this

I know this article has been around the blogshere already and with good reason. This really is a perfect example of Quick Change Overs/SMED being used in a situation that everyone recognizes. It just shows that improvement ideas do not have to big, clever or expensive. In fact the best are usually small, simple and cheap.

Subscribe to:

Posts (Atom)