Catching up on some blogging. The AME regional conference was held in Calgary this year.

The Monday I had been asked to prepare a presentation on 3P, however the potential audience decided that wasn't what they wanted to do. With only a few people signed up to do the session and 10 people required for the hands on workshop part of the session it was a no go. I am hoping to do the session in the future having been part of numerous 3P project and wanting to try out the idea of setting up competing hot dog vendor stalls. Takt times, product variation was all worked out, only thing to do was try it and see if me idea worked. I also had my AP partner Carla all primed to do a section on trust between companies and their suppliers. One of the downsides I see in lots of 3P sessions and similar is the lack of investment between manufacturers and their suppliers. When it's likely that 80% of the end product value has come from your suppliers it is a real loss not having them involved in process design and improvement.

Back to the conference, so instead I was asked to sit in on the Lean Enterprise workshop. I had lots of fun and learnt lots as well. The simulation was similar to the Lego simulation I have run with many companies. It had a couple of differences. The first is how the rounds were played, a more 6sigma approach than Lean and flow. The second was a much stronger emphasis on standard work and quality. Lego blocks are fantastic, which is why we all fondly remember playing with them through our childhood (at least I do). One of the strengths of Lego is how they fit together the bricks line up exactly with each other.

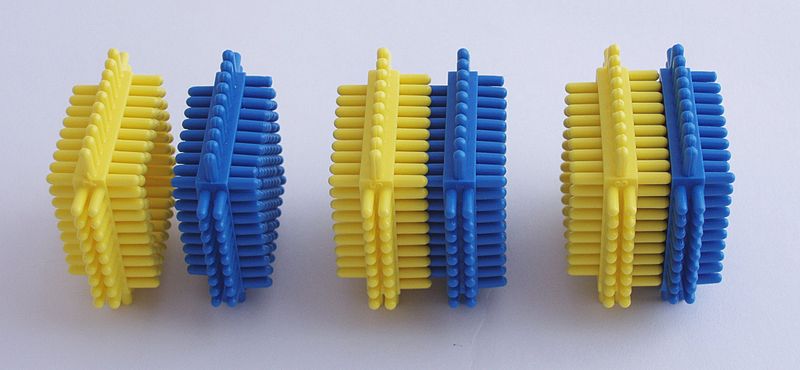

Stickle bricks are different, their orientation is critical to how they line up. If you look carefully you can count different number of 'fingers' on each face. The edges are also different with either 1 or 2 rows of fingers so they can be pushed together. This little detail allowed for far more variation to enter into the assembly process. And this variation was quickly demonstrated in the success or failure of the company. It also powerfully underlined the need for good standard work instructions and inbuilt quality. Lots of food for thought for me.

Thanks to Robert Burke of the VIP Group for letting me sit in.

No comments:

Post a Comment